Difference between revisions of "Robot Electrical Power"

(Tag: Visual edit) |

(Changed categories.) |

||

| Line 38: | Line 38: | ||

[[File:motor wiring.jpg|center|thumb]] | [[File:motor wiring.jpg|center|thumb]] | ||

<br /> | <br /> | ||

| + | [[Category:Electrical Engineering]] | ||

Revision as of 19:09, 5 March 2021

https://www.superdroidrobots.com/shop/custom.aspx/robot-electrical-power-and-wiring/53/

Contents

Summary

Robots need their batteries! Batteries provide power to the robot, and we sell several different batteries. Our motors are 12V or 24V. You can look at the motor pages to see what the current draw is for each motor. If you're using small motors and don't have the robot weighted down, the motors will not draw much juice so a small mAhr battery pack should be fine. However if you are going to load the robot up and run it in thick carpet or grass, or if you just want a long run time, then the larger AHr batteries would be a better choice.

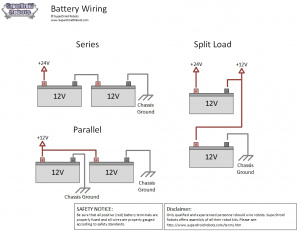

Battery Wiring

When wiring your batteries to your robot, there are concerns you must address. Namely, what output voltage you need and how you are going to charge the batteries. When using two 12V batteries you will need to wire them in parallel to power 12V motors and in series to power 24V motors.

In a parallel setup, the positive (red) terminals are connected together and the negative terminals are connected to the chassis. In a series setup, the negative terminal of Battery1 is connected to ground and the positive terminal is connected to the negative terminal of Battery2. The positive terminal of Battery2 is then connected to your robot. The way this works, is that the electricity from Battery1 travels through Battery2 and their voltage levels are added together. In a parallel setup, both batteries will share the load of your system. Meaning your motor controller and motors will pull from both batteries equally. This will result in an approximately double the running time.

Note: Always be sure to place a fuse after each positive battery terminal for safety. The fuse should be sized so that it is as close to the maximum current, without going under.

For charging, it is always best to be able to charge the batteries individually. Batteries should never be charged in parallel. They can be charged in series, as long as you have a balanced load. This means that your robot should only be pulling power from both batteries equally.

Electrical Battery Connectors

We typically bring out 15A connectors attached to the battery terminals to provide an easy and secure way to charge the batteries on the robot. Depending on the demands of the robot, 15 amp or 30 amp connectors are used. Please see the images below as a demonstration of proper and improper connector crimps and connectors. We only offer red and black connectors for sale, but for reference (if you buy one of our assembled robots) we include a diagram showing our standard color codes for battery connectors we use during assembly to help us distinguish between the type of battery and the voltage.

Typical Power Wiring a Robot

There are lots of different ways to wire up a robot.

The key things to consider are what voltages do you need and how much power the driving force for the main battery will be. We typically use 24VDC motors. They run at half the current for the same power as 12V motors so they use smaller wires, motor controllers, etc. Do you need a separate battery for the controller or on-board computer, etc? How are you going to get those voltages (multiple batteries, voltage regulators, etc.)? How much of a load will be on each voltage so your batteries and/or regulators are sized properly? This will help you size your batteries. Simple math states that if you have a 1Amp load and a 10Ahr (10,000mAhr) battery, the battery will run for 10 hours in theory.

Fuses

These are great to put in all over the place to protect components, but not always necessary. Lots of devices have built in overload protection such as switching regulators, smart battery packs, etc. If you are going to put a fuse in, it should be as close to the battery as possible.

Grounding

This is very important! Good ground is essential to protect the robots' components and for electrical noise. We typically put a single ground lug on the aluminium chassis of the robot. All ground leads come to the same point. You do not want multiple grounding locations leading to multiple ground paths/potentials. This can cause all sorts of unexplained trouble. Care must be taken to make sure multiple grounds are not run to the same piece of equipment. This is most common with the motor controller. The signal coming in is usually carrying a ground signal as is the power to the motor controller. This results in a potential ground loop. The signal's ground typically should not be used as it's getting its ground from the power.

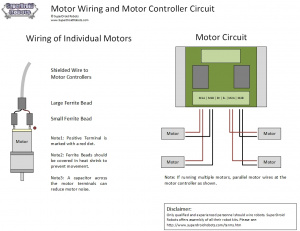

Electrical Motor Hookup

Electrical noise is one of the most frustrating issues when working on robots with DC motors. The EMF coming from the motors will wreak havoc on the microcontrollers, any RF equipment, or other sensitive electronic equipment. We recommend you use the following kits to wire your motors. These kits will provide the wiring from the speed/motor controller to the motors. You will need one kit per motor. Follow this link for more information on how to hook up the motors.