Difference between revisions of "How to Add Encoders to a Robot"

(Tag: Visual edit) |

(Tag: Visual edit) |

||

| Line 56: | Line 56: | ||

===Roboclaw Motor Controller=== | ===Roboclaw Motor Controller=== | ||

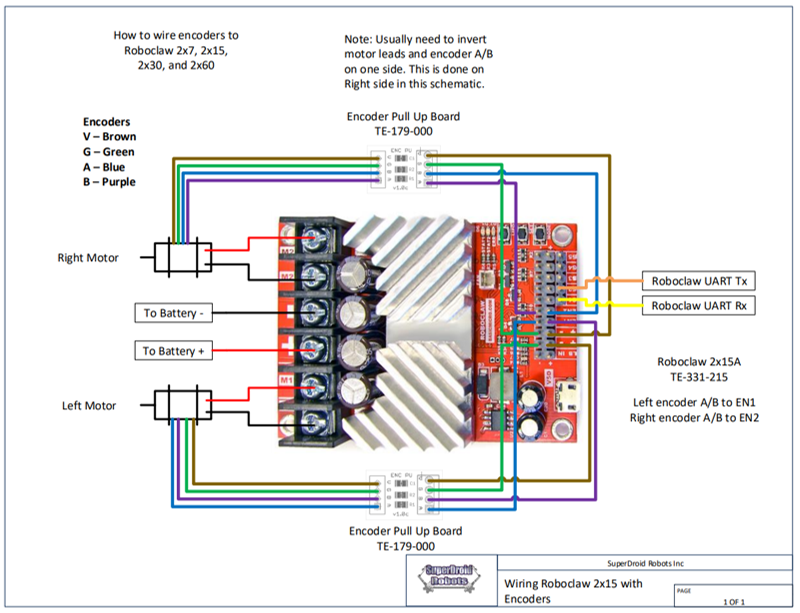

Roboclaw motor controllers are able to connect directly to the encoder quadrature signals and keep track of the number of pulses observed. Roboclaws can use the measured encoder data to perform [[Speed Control#Closed Loop|closed loop speed control]]. | Roboclaw motor controllers are able to connect directly to the encoder quadrature signals and keep track of the number of pulses observed. Roboclaws can use the measured encoder data to perform [[Speed Control#Closed Loop|closed loop speed control]]. | ||

| + | [[File:Roboclaw Encoders Schematic.png|center|frame|Roboclaw 2x15 with Encoders Schematic]] | ||

| + | <br /> | ||

===Encoder Buffer Board=== | ===Encoder Buffer Board=== | ||

This board is always an option when the robot's motor controller (such as a Sabertooth) does not support encoder reading. This device uses the LS7366R chip and connects directly to the encoders, maintains a count of the encoder pulses, and provides a SPI interface to read the counts from a microcontroller. We sell this board in 1-, 2-, 3-, and 4-channel variants. The board provides optional pullup resistors for the encoder A and B signals so no additional circuitry is required. | This board is always an option when the robot's motor controller (such as a Sabertooth) does not support encoder reading. This device uses the LS7366R chip and connects directly to the encoders, maintains a count of the encoder pulses, and provides a SPI interface to read the counts from a microcontroller. We sell this board in 1-, 2-, 3-, and 4-channel variants. The board provides optional pullup resistors for the encoder A and B signals so no additional circuitry is required. | ||

Revision as of 17:45, 22 January 2021

This is a practical guide to adding encoders to a robot. Encoders are added to a robot's drive motors in order to track wheel speed, distance traveled, and/or implement closed loop speed control.

In addition to the encoders themselves, extra components and circuitry are needed to interface with and keep track of the encoder output over time. This guide will cover how to select the correct options to add encoders to a robot kit and go into more detail about the required components.

Contents

[hide]Adding Encoders to a Robot Kit

If you're purchasing a robot from SuperDroid Robots, if you want to add encoders to the robot then follow these guidelines when selecting options.

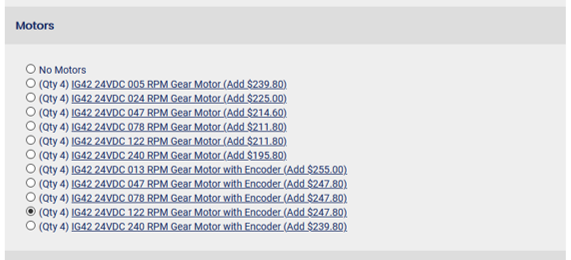

- Motors: Make sure to select motors with encoders! Most kits will have options for motors with and without encoders. To have encoders on the robot, you will need to select an option that says "with Encoders".

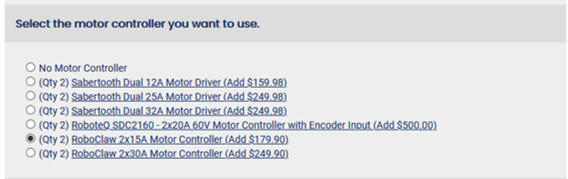

- Motor Controllers: If you're not sure what to pick here then consult the Reading Encoders section of this page. Essentially Roboteqs and Roboclaws are able to interface directly with encoders but Sabertooths will require a separate Encoder Buffer Board and microcontroller to read encoder values.

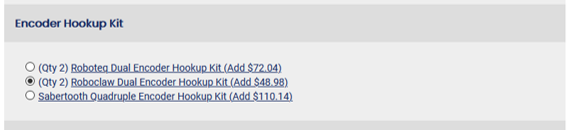

- Encoder Options: Pick the Encoder Kit that corresponds to your selected Motor Controller. Note that there are three versions of Sabertooth Hookup Kit (Dual, Triple, and Quadruple) because they each come with a different version of the Encoder Buffer Board based on the number of wheels that need to be monitored. The Roboclaw and Roboteq kits are only designed for 2 encoders and will simply come in a set of 2 when three or four wheels will have encoders.

Encoder Hardware

Encoders can either come attached to the motor or installed separately as standalone units.

Motors with Encoders

Our IG32, IG42, and IG52 gear motors come in variants with and without encoders. In the picture to the right, the encoder is inside the black end cap. There are four wires coming out of the encoder unit that provide access to the encoder power and quadrature A and B pulse signals.

| Wire Color | Function |

|---|---|

| Brown | 5V Power Input |

| Green | Ground |

| Blue | Quadrature A |

| Purple | Quadrature B |

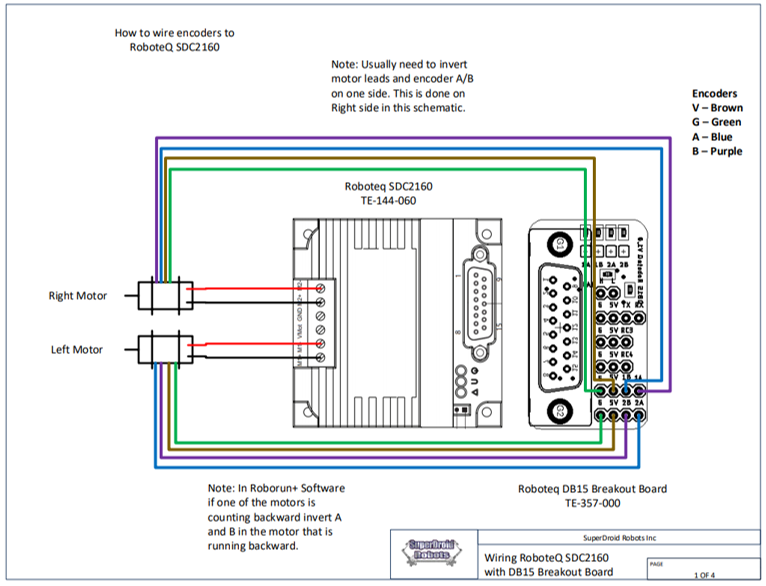

With these encoders, the A and B signals must have 1k pull-up resistors connected between each signal and the encoder 5V power. When we install these on our robots we include these resistors on either a Roboteq DB15 Breakout Board, Encoder Buffer Board, or Encoder Pullup Board, depending on the motor controller used.

Standalone Encoders

There are standalone encoder units that can be purchased and installed on a robot separately from the motors. These are less convenient since they need to be mechanically mounted and somehow coupled to the motor or drive shaft instead of being part of an all-in-one solution. We don't usually offer these as options but we do use them in situations where the motors do not offer encoder variants (such as on the HK1000, which uses wheelchair motors).

Reading Encoders

We have a few preferred methods for tracking and reading encoder values.

Roboteq Motor Controller

Roboteq motor controllers include built-in functionality to connect directly with the encoder A and B quadrature signals, detect pulses, and maintain a count of the number of pulses observed. Roboteqs can use the measured encoder data to perform closed loop speed control.

Roboclaw Motor Controller

Roboclaw motor controllers are able to connect directly to the encoder quadrature signals and keep track of the number of pulses observed. Roboclaws can use the measured encoder data to perform closed loop speed control.

Encoder Buffer Board

This board is always an option when the robot's motor controller (such as a Sabertooth) does not support encoder reading. This device uses the LS7366R chip and connects directly to the encoders, maintains a count of the encoder pulses, and provides a SPI interface to read the counts from a microcontroller. We sell this board in 1-, 2-, 3-, and 4-channel variants. The board provides optional pullup resistors for the encoder A and B signals so no additional circuitry is required.

Single LS7366R Encoder Buffer Board (TE-183-001)

Dual LS7366R Encoder Buffer Board (TE-083-002)