Difference between revisions of "How To Build a Robot"

(Changed categories.) |

(Changed categories.) |

||

| Line 331: | Line 331: | ||

[[Category:Electrical Components]] | [[Category:Electrical Components]] | ||

[[Category:Sensors]] | [[Category:Sensors]] | ||

| + | [[Category:Mechanical Engineering]] | ||

Revision as of 19:32, 8 April 2021

Contents

General Robot Building Questions | The Big Picture

Building your own robot can be a fun and instructional experience. It can be a little frustrating though when you are not sure about a certain aspect of the build. This is a step by step guide that will help you get your robot up and running. In this guide we will go over some robot basics, help you with part selection, and give some assembly advice. To get started you can use answer some of the questions on our Custom Robot Request Page. These will help you figure out the type of robot you want to build and help a little with part selection. You may also submit the form if you would like to skip the DIY and have SuperDroid Robots and its professional staff build it for you.

Some questions you will want to ask yourself

- What is my budget?

- What is my schedule?

- What do I want the robot to do?

- What type of terrain will it be used on?

- Do I have any size requirements or restrictions?

- Do I have any weight requirements or restrictions?

- Do I want it to be weather resistant? Weatherproof? Waterproof?

- Do I have any additional capacity requirements for volume and/or weight?

- How do I want to control it? Wireless, tethered, Autonomous, RC, WiFi, Fiber Optics, IR, etc.

- How long of a run time will I need? Will it be run continuously or intermittently during this time? (i.e. what is the required duty cycle?)

- Do I want to build using just parts, a kit, or a completely assembled ready-to-run robot?

The basics of our robot kits

Our robot kits are developed based on years of experience designing custom robots. All the components are designed to work together. If you do not have much experience building robots, the easiest thing to do will be to start with one of our robot kits. If you start from scratch you'll have to make a lot of decisions about size/speed of motors, size and type of wheels, type and capacity of batteries, and many more. Making these decisions can require experience and some trial and error. With our robot kits, we have made many of these decisions already and taken most of the guesswork out of the equation. All of our robot kits have options listed at the bottom of the page allowing you to configure the robot with parts that will work together.

Most of our robot kits can be purchased in kit form (unassembled) or assembled. If you have never built a robot or you do not have much experience with soldering and mechanical assembly, we recommend you opt for us to assemble it for you. We will have our experienced technicians assemble and test it. If anything is not right (such as a defective motor or motor controller, battery charger, etc.) we will replace it and make sure everything is ready to run when you receive it.

How does a robot turn?

Most of our robots use brushed DC gear motors to power the wheels or tracks. Many of them are 4WD or tracked platforms that use tank style steering or skid steering. This means that the wheels/tracks on either side of the robot turn at different speeds which guides the robot in the direction of the side that is moving slower. Furthermore, by moving all the wheels/tracks on the left side one direction and the right side the opposite direction, the robot can turn in place.

Since the robot has to "skid" to steer, friction is the major factor for sizing your components (most importantly, the motors). The more the robot weighs, the harder it is to turn. The higher the friction coefficient (deep grass, carpet), the harder it is to turn. The lower RPM motors have lower speed, but more torque for easier turning. The default options listed for our robot kits are what we recommend as a good starting point. Contact us if you need help selecting options or need custom configuration.

Let's Get Started!

There are a lot of decisions that need to be made once the general questions are answered. Most of this information is in order. In some cases you can jump around, but basically you cant pick your batteries, until you know what your motors are, and you cant pick motors until you pick a platform, etc.

Tracks or Wheels?

Tracks

Everyone thinks tracks are cool. They are but they also come with complication and price.

Tracks add many advantages:

- Spread your load out for a low PSI rating.

- Make climbing and bridging gaps, such as stairs, much easier.

- Handle more aggressive terrain and loose terrain.

They also offer a lot of challenges:

- Less efficient (track tension adds extra strain to the motors).

- Components are more expensive.

- More complicated design (timing, derailment, and tensioning all must be considered)

Below are the tracks that we sell. Note that the DIY tracks need to be spliced. We also do not offer a solution for wheels for any of them. You will be on your own designing a wheel and tracking system for all of these tracks. Our SDR manufactured sets are what we use in our tracked robot kits. We have designed the tracks and the wheels to work together and the tracks do not have a splice.

SDR Manufactured Tracks and Wheels

For more information on tracked robots, see our HD2 Support, LT2 Support, and MLT-JR Support pages.

Wheels

Wheels are by far an easier and less expensive option than tracks.

Wheeled robots have a lot of advantages:

- More efficient.

- Simpler design.

- Lower cost than tracks.

- In most cases offers has less resistance to turning.

- Some designs allow for a vectoring robot that can move in any direction.

Some of the disadvantages of wheels:

- High centering when going over uneven terrain.

- Less traction on rough and loose terrain.

- Can't climb stairs without making radical suspensions.

Wheel Types

Standard Wheels:

Good for use both indoors and outdoors, these are rubber pneumatic wheels. We offer wheels with low profile tread that are better for smooth surfaces and traction lug tires with a more aggressive tread for rougher terrain.

- Robot Drive Wheel - 6 inch pneumatic tire

- Robot Drive Wheel - 10 inch Pneumatic

- Robot Drive Wheel - Traction Lug 13 x 5.00-6 Tiller Tire

- Robot Drive Wheel - Traction Lug 10 x 3.50-4 Tiller Tire

Omni Wheels:

Omni Wheels have rollers around the edge of the wheel that spin perpendicular to the axis of the wheel. They are a great option for robots that require high payloads since they significantly lower the friction when turning. They also open up the possibility of a vectoring robot by using 3 wheels at a 120 degree angle from each other, or 4 wheels at a 90 degree angle from each other. By individually controlling the motors' speed and direction, you can make the robot move in any direction.

Omni wheels are really only meant for flat smooth surfaces though. The robot will side slip sideways on a hill and dust/dirt can impede the movement of the rollers. They are also quite noisy.

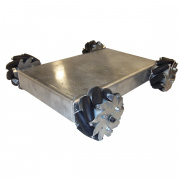

Mecanum Wheels:

Mecanum wheels are similar to omni wheels, except the roller spins on an axis at a 45 degree angle from the wheel axis. These wheels have the same downside as omni wheels in that they cannot handle hills and a dirty environments well and they make a fair amount of noise.

<sdr cagetory id=156>Omni and Mecanum Wheels</sdr item>

We also offer ready-made wheeled platforms:

And omni-wheel robot platforms:

To learn more about wheeled robots see our All Terrain Robots and Vectoring Robots support pages:

Motors

An electric DC motor spins very fast, often in the range of 4000-6000 RPM and has very little torque. This isn't very useful for a robot. Most robots move at relatively slow speeds and need high torque. Luckily, we can use a gearbox to slow the motor down and generate more torque. The more the motor is geared down, the more torque it will have. We use brushed DC gear motors meaning that they come with a gearbox already attached. We categorize the motors first by their size and then we specify the further by their speed.

Your car uses a transmission and starts in 1st gear (most reduced) so you have the low-end torque to start moving. Then, as you speed up, you change gears to get more speed. Most robots, however, cannot change gears. The maximum speed and torque are fixed. You have to find the right balance so you have enough torque to get started from zero speed, but then enough top-end speed. If you gear it down too much you will have plenty of power, but never get any speed. If it's not geared enough it will probably be plenty fast but it will have trouble accelerating, driving up hills, and turning. You need to find a balance where it works well for both. The big electric motors will help because they will muscle through it if you don't have it geared just right, but if it works too hard you will be drawing a ton of current and burning up your batteries!

A few words on motors and axles

Our wheeled robots are named after the size of the gear motor they use. How the wheels are mounted to the motors is also important. We offer three basic styles of robots that use different wheel mounting methods. We do this to offer different solutions to sideloading the motors. Motor gearboxes are not specifically designed to support a load. They are designed to rotate a shaft or apply torque. To protect the motor gearbox with heavier loads, the wheel axle should be supported by the chassis.

- Direct Mount (DM): The wheel and shaft are directly mounted to the motor.

- Single Bearing (SB): The motor is mounted directly to the wheel shaft, but there is an outboard bearing that helps to support the load.

- Double Bearing (DB): This is the most robust configuration. The wheel shaft is supported by the two bearings, and the shaft is chain or belt driven.

For more detailed information on motor mounting, visit our ATR Support page.

Direct Mount ATR

Some platforms use a chassis with a motor bolted to it and a wheel bolted directly to the motor shaft. This works fine for light loads, our IG32-DM4 4WD Robot is a perfect example. The durability of the robot platform is directly related to the durability of the motor and gearbox. The more weight you put on the chassis the more the motor has to support.

Single Bearing ATR

For larger loads we have designed a platform that takes the vast majority of the weight off the motor shaft by adding a longer shaft and supporting it with a ball bearing in the chassis. This platform is demonstrated in our IG32 and IG42 ATR examples. The motor is still coupled to the wheel directly just with a longer shaft that runs through a bearing.

Double Bearing ATR

For even larger loads we designed a platform that takes the load off of the motor completely like our IG42-DB4, IG52-DB4, and IG52-DB4-E. The wheel is bolted to a high strength axle and that is supported by two industrial-grade ball bearings. ANSI #25 chain and sprockets connect the motor to the axle. The bearings bearings take all of the load off of the motor shaft and put it on the chassis. This makes for a truly heavy-duty robot platform.

Robot Speed Calculator

This is a helpful tool to figure out the speed of your robot. Input the RPM your motor, any chain reduction (if direct drive use 1), and the outside diameter your wheel or track.

The Robot Speed Calculator has been moved here.

Chain or belt drive motors to wheels

Chain driving also provides another opportunity to gear down the robot to a desired speed. If you are not sure what size motor will work for you then the chain driving can offer some flexibility with speed and torque without having to change the motors. We offer chains and sprockets for doing all sorts of gear reductions. If you want the motor to spin the same speed and have the same torque as the motor, then you go 1:1 (i.e. a 15 tooth to a 15 tooth). If you want more torque and less speed then you gear it down like 1:2 (15 teeth to 30 tooth), so the motor will turn two times for per 1 wheel revolution resulting in half the speed, but twice the torque. If you have plenty of torque but want to speed things up you can go 2:1 (i.e. 30 teeth to 15 teeth) so every turn the motor makes the wheel will make 2, but you will have half the torque. The advantage of the chain drive is you can select any combination of reductions to tune your robot to work best for the payload and terrain. You want to try to tune it so the motor works at its peak efficiency during normal operation. Typically you do not want to gear up too much because you lose some efficiency with reductions. So if you are using a gear motor and have a 1:17 reduction in the gear motor, then use a 3:1 speed up, you are losing a lot of your power due to the inefficiency of gearing. We have several motors to choose from. If you are still having trouble deciding on the motor, select one of the pre-built kits that already have the motors selected as default.

If you are doing a very small robot see our Servo Modification Support Page so you can use hobby servos and modify them for continuous rotation.

Available Motors

- Servos - Very small robots < 5 lbs

- 32mm Gear Motors - Small to medium robots 5-35 lbs

- 42mm Gear Motors - Small to medium-large robots 5-50 lbs

- 52mm Gear Motors - Medium to large robots 25-150 lbs

- 90mm Gear Motors - Large robots up to 250 lbs

- Micro Metal Gear Motors - Very small robots < 5 lbs

- Wheelchair Motors - Large robots up to 250 lbs

Motor Controllers

Motor Controllers take signals from a microprocessor or radio control receiver and convert it into a high current varying voltage. Motor controllers are rated based on the voltage and current requirements. You can take a look at some of our robot kits to get an idea of what size motor controller you will need. We carry RoboteQ motor controllers, which will take encoder inputs for speed and/or position control, as well as Dimension Engineering's Sabertooth with a Kangaroo for encoder input.

For more help with using encoders with motor controllers, please visit our Motor Controller Support Page, and our Encoder Support Page.

For Help selecting the right motor controller, review each item and their associated data sheets / manuals.

For a complete list of all of our motor controllers, follow this link.

- Roboteq’s XDC2460 controller is designed to convert commands received from an RC radio, Analog Joystick, wireless modem, PC (via RS232 or USB) or microcomputer into high voltage and high current output.

- RoboteQ MDC2460 - 2x60A 60V Motor Controller with Encoder Input Roboteq’s MDC2460 (2x60A 60V) controller is designed to convert commands received from an RC radio, Analog Joystick, wireless modem, PC (RS232 or USB) or microcomputer into high voltage and high current output for driving one or two DC motors.

- RoboteQ SDC2160 - 2x20A 60V Motor Controller with Encoder Input Roboteq’s SDC2160 (60V) controller is designed to convert commands received from an RC radio, Analog Joystick, wireless modem, PC (RS232 or USB) or microcomputer into high voltage and high current output for driving one or two DC motors.

- Sabertooth Dual 32A Motor Driver The Sabertooth 2X32 is one of the most versatile, efficient and easy to use dual motor drivers on the market. It is suitable for medium powered robots - up to 30lbs in combat or 100lbs for general purpose robotics. Made by Dimension Engineering.

- A4988 Stepper Motor Driver Carrier with Voltage Regulators The A4988 stepper motor driver carrier with voltage regulators is a breakout board for Allegro’s A4988 microstepping bipolar stepper motor driver.

- A4988 Stepper Motor Driver Carrier The A4988 stepper motor driver carrier is a breakout board for Allegro's A4988 microstepping bipolar stepper motor driver.

- DRV8825 Stepper Motor Driver Carrier, High Current The DRV8825 stepper motor driver carrier is a breakout board for TI's DRV8825 microstepping bipolar stepper motor driver.

- Pololu Zumo Shield for Arduino This shield mounts onto an assembled Zumo chassis and makes it easy to build an Arduino-controlled Zumo robot.

- Pololu DRV8833 Dual Motor Driver Carrier This tiny breakout board for TI’s DRV8833 dual motor driver can deliver 1.2 A per channel continuously (2 A peak) to a pair of DC motors.

- Dual MC33926 Motor Driver Shield for Arduino This shield makes it easy to control two brushed DC motors with your Arduino or Arduino-compatible board. Its dual MC33926 motor drivers operate from 5 to 28 V and can deliver a continuous 3A per motor.

- Dual VNH5019 Motor Driver Shield for Arduino This shield makes it easy to control two high-power DC motors with your Arduino or Arduino-compatible board.

- Sabertooth Dual 60A motor driver Dimension Engineering Sabertooth 2X60 is one of the most versatile, efficient and easy to use dual motor drivers on the market. It is suitable for high powered robots - up to 120lbs in combat or up to 1000lbs for general purpose robotics.

- SyRen 50A Regenerative Motor Driver Out of the box, the SyRen 50 can supply a single DC brushed motor with up to 50A continuously. Peak currents of 100A are achievable for a few seconds. Made by Dimension Engineering.

- Sabertooth Dual 12A Motor Driver Dimension Engineering Sabertooth 2X12 is one of the most versatile, efficient and easy to use dual motor drivers on the market. It is suitable for medium powered robots - up to 30lbs in combat or 100lbs for general purpose robotics. Replaced TE-091-210.

- Sabertooth Dual 12A RC Motor Driver Sabertooth 2X12 R/C is a dual motor driver specifically optimized for use in radio controlled vehicles. The Sabertooth 2x12 RC replaces our custom 2x10 RC controller. Made by Dimension Engineering. Replaces 2x10 RC (TE-115-210).

- Sabertooth Dual 5A Motor Driver The Sabertooth 2X5 is one of the most versatile, efficient and easy to use dual motor drivers on the market. It is ideal for smaller robots- up to 3lbs in combat or 25 lbs for general purpose use. Made by Dimension Engineering.

- MD22 Devantech Dual Motor Driver The MD22 by Devantech is a robust low/medium power motor driver. The driver is designed to supply power for two independent motors.

- RoboClaw 2x60A Motor Controller The RoboClaw 2x60A is an intelligent motor controller designed to control two brushed DC motors at 60 Amps continuous with up to 120 Amps peak per channel.

- RoboClaw 2x30A Motor Controller The RoboClaw 2x30A is an intelligent motor controller designed to control two brushed DC motors at 30 Amps continuous with up to 60 Amps peak per channel.

- RoboClaw 2x15A Motor Controller The RoboClaw 2x15A is an intelligent motor controller designed to control two brushed DC motors at 15 Amps continuous with up to 30 Amps peak per channel.

- RoboClaw 2x7A Motor Controller The RoboClaw 2x7A is an intelligent motor controller designed to control two brushed DC motors at 7.5 Amps continuous with up to 15 Amps peak per channel.

- RoboClaw Solo 30A Motor Controller The RoboClaw Solo 30A is an intelligent motor controller designed to control one brushed DC motors at 30 Amps continuous with up to 60 Amps peak.

A very common question that we get is "how do I hook up four motors to a two-channel motor controller?" Most of our 4WD robots use four motors (one motor per wheel).

Since the left motors need to act together as do the right motors, the solution is very easy. Just parallel the left motors to one channel of the motor controller, and parallel the right motors to the second channel.

The same goes for 6WD robots. Just make sure the sum of the stall torque for each motor does not exceed the motor controller rating. (ie: 2 motors with 15A stall will exceed the rating of a 25A controller in a stall condition.

Robot Batteries

When selecting the appropriate batteries for your robot, you need to size them by voltage to match the desired motors and motor controller. You will also need to take into consideration the maximum current output and the battery type and capacity.

Voltage Rating

Our motors are rated for either 12V or 24V. Incorrectly providing a 24V source to a 12V motor will immediately cause permanent damage. If only connected for a short period of time the observed damage will be limited to a whining sound when the motor is moving. A prolonged over-voltage condition will cause catastrophic damage to the motor and this may pose a significant risk of fire, injury, or death. Be sure that the appropriate power is applied to the motors. If the motors receive insufficient voltage, say 12V to a 24V motor, the motor will either move very slow or not at all.

In order to distribute the weight of a battery evenly across the robot, its common practice to use multiple 12V batteries to prevent the robot from favoring one side while driving. For a 12V motor system, the batteries will need to be connected in parallel and for a 24V system, they will need to be connected in series.

Note: When using a multiple battery system, always be sure that each battery is individually fused.

Maximum Current Output

When selecting the appropriate battery source, it is wise to be sure that the battery can produce the amount of current needed by your motors and motor controller. Take, for example, Dimension Engineerings Sabertooth 2x12 motor controller. It has two channels and each channel is capable of outputting 12A so for the motor controller to be able to supply a total of 24A to a pair of motors the battery providing power to the system must be capable of supplying that amount of current. It is important to note that the motor system may not be the only major component in your system. Be sure to account for the additional loads on your system, such as a computer, control system, sensors, and a radio.

Note: For many hobby RC motors, the batteries will be marked with a C rating. This rating will indicate the maximum continuous current discharge that the batteries are capable of. The C rating is a multiplier that can be applied to the battery capacity to get your maximum continuous discharge. For example, a 2,000mAh 10C battery can output a maximum of 20,000 mA or 20A.

Battery Type and Capacity

There are two main types of batteries that are discussed here: Lead Acid, Lithium. Lead-acid batteries are the cheapest out of the two. These are the batteries that you typically see in a car or a truck. They do not require special circuit protection, only a fuse. The downside is that they are large and very heavy.

The second type are Lithium batteries. You will typically see in most electronics today. They are lighter and more compact than lead-acid batteries and are the go-to battery type for RC robotics. One caveat that with Li-ion batteries is that they require specific under-voltage circuit protection to prevent the battery from dropping too low. If this happens the battery will be unrecoverable. Most of our Lithium batteries contain the necessary circuit protection to prevent this from happening. Most of the cheap RC batteries you see listed online, do not.

There are several kinds of Lithium batteries. Lithium-ion is the most common (and the most unstable). Lithium-ion require extreme care so they do not overheat, etc resulting in a fire or explosion. A more stable battery is LiFePO4 chemistry as in our K2 25.6V or K2 12.8V batteries. These batteries are much more stable and an excellent choice for powering robots, but they are more expensive.

On the topic of battery capacity, it is commonly measured in mAHr (milliamp hours). This is a measurement of how long it would take to discharge the battery if it outputted 1mA of current. Larger batteries are typically measured in AHr which is mAHr divided by 1,000. So, a 12V 2000 mAHr (2AHr) battery will last twice as long, under the same conditions, like a 12V 1,000 mAHr (1AHr) battery.

Robot Battery Chargers

When ordering a robot kit as a base for your project, we offer appropriately sized chargers for the supplied batteries. When picking out your own chargers, it is absolutely critical that you pick the charger with the correct voltage and battery type. Not selecting the appropriate charger will be a fire hazard and cause permanent damage to the battery, charger and your property.

Robot Controller

There are several options for controlling your robot. The big division of remote control is between Analog versus Digital Control.

Analog

Analog Control provides the simplest link between the operator and the robot possible, it is, however, one way. Video is typically transmitted back over an open analog channel. Analog video transmissions can be viewed on any receiver, both yours or anyone else. Analog Remotes similar to R/C Aircraft can be used to control the robot, or a custom controller can be made to control and display the video in a case. We offer several types of analog controllers.

(RC) Control: (Handheld wireless control devices)

- Spektrum DSMX DX6i Transmitter Only This is a 6-channel 2.4GHz DSMX aircraft system transmitter.

- Spektrum USB-Interface This is a 5-channel 2.4GHz DSM2 aircraft system transmitter. It replaces the DX5e transmitter (as of 12/18/15).

- Spektrum DSM2 AIRMOD w/AR7010 FUT-Compatible Each module system includes everything you need to equip your Futaba module-based system with the interference-free, glitch-free precision of DSM2.

- Spektrum AR6110e DSM2 ML 6Ch Fail Safe Receiver Spektrum’s 2.4GHz DSM2 technology gets even smaller with the AR6110e 6-channel DSM2 Microlite Park Flyer Receiver with End Pins. Ideal for compact airframes or small robots!

- Spektrum Remote Receiver Extension - 36 inch This is a 36-inch remote receiver extension for Spektrum.

- Spektrum Remote Receiver The remote receiver can be used as a replacement for the AR6200, AR7000 and the AR9000 remote receivers. It can also be used as an optional fourth remote receiver for the AR9000.

Picture

For more help with Remote Control (RC), please visit our Remote Control Support Page.

Digital Control

Digital Control of a robot uses Ethernet over a wireless link to control the robot. The wireless link will be over standard WiFi, CoFDM, or a Dual Band Wireless Link similar to WiFi. Our Digital Remotes are enclosed in a Pelican (or Pelican-like) case that houses the radio, control joysticks and switches, and the video monitor.

Digital Wireless Control Systems

- Routers and Bridges: Routers and Bridges to provide Wireless capabilities to your robot!

- Wi-Fi Control Packages: Pre-configured WiFi control systems to get your robot up and running! These control systems come assembled and tested by our staff to ensure out-of-the-box functionality.

XBee, Zigbee, and RF Wireless Communication : These modules allow a very reliable and simple communication between anything with a serial port! Point to point and multi-point networks are supported.- Tactical Robot Controllers: There are many ways to control a robot. We offer a wide range of military grade tactical controllers. Find the controller that works best for you.

- Antennas and Pigtails: 2.4 Ghz antennas and pigtails for wireless routers and radios

For more help with Remote Control (RC), please visit the following support pages: * Remote Control Support Page * Network and WiFi Support Page * Wireless Serial Support Page * Tactical Robot Support Page

Pictures

Complete Control Packages

We offer Complete Control Packages to control the robots. These are complete systems that are custom configured to your needs that will connect your robot.

- Programmable RC Control Interface Package: This package offers the simplicity of manual RC control while having access to the diversity of Arduino I/O.

- Programmable GPS Navigation Package: This package includes all the items you would need to make a robot drive to GPS waypoints autonomously.

- WiFi Remote System with Tablet OCU: This package is for controlling SuperDroid Robots. It contains a WiFi Router, Serial Bridge, Power Supplies, Custom Controller Board, Video Server, Tablet with custom robot control and interface with video monitoring.

- Programmable xBee Control Interface Package: This package allows you to control a robot, out of the box, using the power of Arduino and xBee. The remote comes standard with an ABS enclosure and your option of 2, 3, or 4-axis joystick.Full source code is provided!

- Programmable WiFi Custom Control Interface Package: Fully configured, tested, and supported. This package comes with a network device, Arduino Mega control board, Arduino Ethernet Shield V2, SDR Arduino Mega Sensor Shield, and a 4x TTL relay board. It will fit on top of any of our chassis options.

- ROS Autonomous Control Package: This package provides a completely assembled and configured Robot Operating System (ROS). ROS is a Linux based meta operating system for your robot with a massive open source community.

Autonomous Control

This is a huge topic due to all of the self-driving cars, etc. This, however, is not a simple or trivial task. Google has spent billions of dollars in development.

If you are interested in building an autonomous robot, then please follow these links to help get you started.

- Programmable Arduino Robots: (LINK: cat 157) Programmable Robots. These mobile UGV robots have an Arduino for their controller. These Arduino robots are easy to program and a powerful processor allowing the user to create autonomous robots.

- Programmable Robots: (LINK: cat 194) Programable Robots. Autonomous Robots. Robots that think on their own and do set tasks. They range from customized Arduino WiFi robots to programmable tactical robots.

- Control Systems: (LINK: cat 206) These custom control systems will allow you to control your robot wirelessly,autonomously, or both. Autonomous GPS navigation. Control and monitoring your robot wirelessly over WiFi. If you need something custom, contact us.

- Programmable SDR Robots: (LINK: cat 75) These programmable robots are designed by SuperDroid Robots. They range from customized Arduino WiFi robots to programmable tactical robots.

- Sensors: (LINK: cat 35) We have sensors to help you detect gasses, conduct surveillance, and measure performance. These sensors can help toward building an autonomous robot.

- Build an Autonomous Robot: Bought one of our robots? Want to make it autonomous? Start here! We walk you through design decisions and the required components for you to develop your own autonomous robot.

- Autonomous Robot Services: Autonomous robots are a challenge as they require a precise blend of mechanical, electrical, and software engineering. We have the capabilities to design and develop the autonomous solutions you require.

- Autonomous WiFi Robot Arduino Robot Programming: The page describes the method and gives examples of how we programmed the Free Autonomous WiFi Robot Arduino Robot in our give away.

- Sensor Support: We carry a large array of sensors to enable you to develop a smart and autonomous robotic solution.

Wiring

Power and Battery Wiring

When wiring your batteries to your robot there are concerns you must address. Namely, what output voltage do you need and how you are going to charge the batteries. When using two 12V batteries you will need to wire them in parallel to power 12V motors and in series to power 24V motors.

The key things to consider are what voltages do you need and how much power The driving force for the main battery will be the motors. We typically use 24VDC motors, they run at half the current for the same power as 12V motors so smaller wires, motor controllers, etc. Do you need a separate battery for the controller or on-board computer, etc? How are you going to get those voltages (multiple batteries, voltage regulators, etc.)? How much of a load will be on each voltage so your batteries and/or regulators are sized properly? This will help you size your batteries: simple math. If you have a 1Amp load and a 10Ahr (10,000mAhr) battery, the battery will run for 10 hours in theory.

For more help with wiring, please visit our Robot Wiring Support Page.

Motor Wiring

Generally motors are wired to a motor controller to provide speed control to motors. The motor controller can be used to change the directions of the motor as well. If running motors in parallel (as in a 4WD the two left and the two right motors will be running together in parallel) you can wire them in parallel too.

We have a lot of information on how to wire motors, etc. on our Motor Wiring Support Page.

For more help with wiring, please visit our Motor Wiring Support Page.

Sensors

We offer a wide range of sensors. The more sensors used, the better the autonomy will be. Relying on only one type of sensor for all your positioning will work for simple situations, but will probably cause issues for any complex positioning or for any positioning that requires higher precision.

In robotics, sensors can be used to monitor your environment or to determine your robot's position relative to some object. Standard sensors for environment monitoring can range from temperature thermocouples, gas, and radiation. The standard positioning sensors are Sonic and IR for object detection and GPS, gyroscopes, and accelerometers to determine relative location, direction, and airspeed. For ground travel and RPM feedback, a combination of our encoder enabled motors and our encoder buffer board make it incredibly easy to implement your own speed control algorithms and RPM feedback. The encoder can also be used to keep track of the distance traveled, but with skid steer the more you turn/skid the more inaccurate the reading because of the wheel slips/skids resulting in encoder counts, but no relative movement.

- For a complete list of our available sensors, please visit this link (LINK: cat 57).

- Accelerometers, Gyros, GPS, & Compasses: Accelerometers, Gyros, GPS, & Compasses. Measure acceleration and track rotation with these accelerometers, gyroscopes, compasses/magnetometers, and combined inertial measurement units (IMUs) and orientation sensors.

- Contact Sensors: Contact Sensors. Switches and Bumper Switches used to indicated when a physical limit has been reached.

- Current Sensors: An assortment of unidirectional and bidirectional Hall effect-based current sensors. They offer a very low-resistance current path and electrical isolation between the current source and the measuring circuit.

- Force Sensors: Force-sensing resistors (FSRs) are passive components that exhibits a decrease in resistance when there is an increase in the force applied to the sensor allowing you to create a sensor that is able to detect force or pressure.

- Gas Sensors: Gas sensors makes it possible to measure concentrations of gasses such as alcohol, methane, propane, butane, and carbon monoxide.

- Magnetic Guide Sensors: Precision magnetic sensor for detecting and measuring the position of a magnetic track along the horizontal axis, for use in Automatic Guided Vehicles and other Automation applications.

- Optical Sensors - IR, PIR, Photo, & Lasers: Optical IR Sensors & Laser Range Finders. IR distance sensors make it easy to detect and range objects. The laser range-finder is inexpensive, accurate and easy to use with a 240 degrees scan area.

- Sonar Range Finders: Accurately measure distances over a wide range with our assortment of ultrasonic distance sensors from Maxbotix and Devantech.

- Temperature and Humidity Sensors: These sensors measure the humidity of the air and can measure the temperature. Great features for your microcontroller project.

For more detailed information on sensors, visit our Sensor Support page.